It is with a note of sadness that I must report that my perfectly operating Suzuki SV650S on it’s approach to four years of faithful service has started to show signs of weakness. Not mechanical failures per say, but design failures. While they are very reliable motorcycles there are three specific flaws that I have run across with this bike.

The first problem I ran across is documented in the article on push starting a motorcycle.

The second design issue is one that is potentially dangerous, and well documented. I first noticed it when I was riding on a rainy day, the bike seemed to cut out, or lose power. I’ve run across similar problems when I’ve had voltage regulator rectifiers fail. This was different in that it would suddenly surge back on, and then drop out again…imagine losing all the power in the engine and then having it pop back on a wet slippery road in the middle of traffic, or while negotiating a turn. That’s why this is a particularly dangerous design flaw. It turns out that the front cylinder gets hosed down by the spray off the front wheel, drowning the front spark plug. When this happens the front cylinder fails to fire, the water evaporates, or partially drains, then the spark starts again. Bad. There is a drain hole in the front cylinder, but it tends to clog according to a few owners. One of the more typical solutions would be a fender extension that would deflect the water before it even hits the radiator. I opted for a different approach. I knew that I could fabricate something overnight, rain was forecasted for the next day, but nothing that would look good to attach to the front fender. So I fabricated an aluminum plate to go over the front cylinder. It needed to curve to clear the radiator brackets, but be large enough to keep the water out. An hour later I had a cool little plate that was just right, and zip tied it to the breather hose off the top of the cylinder head. I’ll snap a picture next time I need to get behind the radiator.

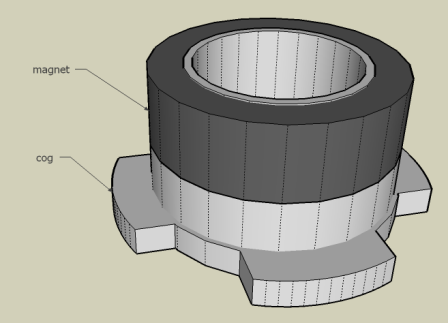

The other horrible design that just presented itself is the front wheel speedometer magnet. The magnet is a flexible ferrite magnet, the soft refrigerator magnet material. I know why they designed it with this material, it’s easy to manufacture, cheap. The ferrite is mixed into a polymer and cast into the exact shape required to fit the application. Unfortunately this is a mechanical part that is under some stress and the present material is prone to disintegration. The front wheel hub has four notches and the magnet has four splines, like a gear, and as the wheel turns the magnet is spun actuating the magnet switch and triggering the speedometer. This is the exact system used in cycling computers. A better design would be one that uses a harder, ABS spline bonded to the magnetic tube. That way the stress of the front wheel would drive a more durable material and be less prone to failure. I have included a small Sketchup sketch of the idea for this design. For those that are interested in a free awesome 3D application you should check out Sketchup on the Google apps page.

These modifications might cost a bit more during the manufacturing process, but the pay off for the manufacturer is a more reliable product and a happier customer.